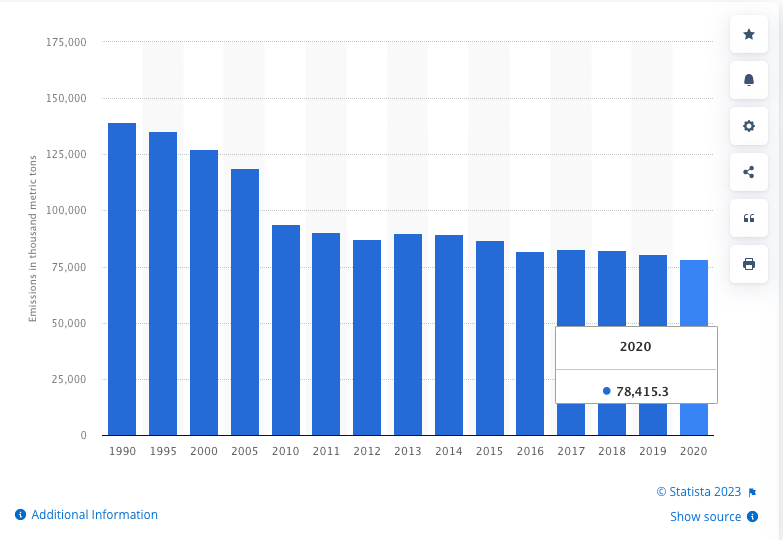

Decarbonisation is a crucial stake for all companies, given that the industrial sector is responsible for 19% of greenhouse gas emissions in the UK. In 2021 it was directly responsible for emitting 9.4 Gt of CO2, accounting for a quarter of global emissions. While progress has been made in this sector since the 1990s, the manufacturing industry (part of the industrial sector) alone produced 78.4 million metric tons of carbon dioxide emissions in 2020 just in the UK. Nonetheless, there has been a reduction of over 40% in manufacturing industry emissions compared to 1990 levels, as demonstrated in the chart below. The industrial sector has the potential to significantly reduce GHG emissions and play a vital role in achieving the environmental objectives set by the government. Therefore, it is crucial for these companies to take proactive measures towards decarbonisation.

Although sustainability is often presented as a regulatory obligation, it also represents a significant competitive advantage. In this article, we explore the importance of decarbonisation for industrial companies, both from an environmental and economic perspective and present some key solutions to achieve it, with a focus on the EU and the UK.

Industrial Decarbonisation

Industrial Sector: focus on the UK and Europe

The industrial sector is a key economic sector in the United Kingdom and comprises over 2.5 million businesses. In 2020, it employed around 10 million people in the UK and 67 million in the EU. It’s worth noting that the industry covers a wide range of fields, such as manufacturing (which represents the majority at 55% in the UK), as well as mining, electricity, gas, and water sectors. The manufacturing industry alone contributes approximately 9.2% of the UK’s GDP and 15% within the European Union.

Decarbonisation of the Industrial Sector

The term decarbonisation refers to the set of measures enabling an entity to reduce its GHG emissions in order to limit its impact on the climate. In the case of an industrial company, this may involve reducing emissions from the industrial process, for example.

Why is it important to decarbonise the industrial sector? There are many reasons:

- Firstly, there is an obvious environmental concern, whether to meet existing regulations or to satisfy a corporate social responsibility (CSR) policy set by the company itself.

- In addition, in some cases, banks may require a high level of CSR performance before granting financing.

- Finally, the economic aspect of decarbonising the industrial sector should not be overlooked. This approach can generate significant savings while maintaining the company’s competitiveness. Indeed, it can lead to the improvement of processes and the overall efficiency of industrial sites. But also the ability to face the constant increase in energy prices thanks to the better energy efficiency of the installations. It should be remembered that, faced with an inflationary context, many industrialists have had to reduce their production, or even stop it completely, in order to survive during the winter period.

Thus, the decarbonisation of the industrial sector has become an unavoidable priority. It is also a source of value for your company and an opportunity to implement measures to reduce greenhouse gas emissions that will greatly contribute to improving the performance of your industrial site.

General decarbonisation objectives in the UK and in the EU

- European Union

To meet the objectives of the Paris climate agreement, the European Union has set itself a target of reducing GHG emissions by 55% by 2030 compared to 1990, and achieving carbon neutrality by 2050. The EU is also actively supporting the transition to a low-carbon economy through funding and investment programs, such as the European Green Deal Investment Plan and the Horizon Europe research and innovation program.

- United Kingdom

The UK government has set out a comprehensive decarbonisation strategy to meet its ambitious target of achieving net-zero greenhouse gas emissions by 2050. The strategy is based on several key pillars, including:

- Investing in renewable energy: The UK is increasing its investment in renewable energy, including wind, solar, and hydropower, to reduce its reliance on fossil fuels. The government set a target of installing 40GW of offshore wind capacity by 2030, which will help power homes and businesses across the country. In this article, we discuss the UK’s energy mix.

- Phasing out fossil fuels: The UK is phasing out the use of coal, with plans to close all coal-fired power plants by 2024. The government is also planning to phase out the sale of new petrol and diesel cars and vans by 2030, with a goal of achieving 100% zero-emission new car and van sales by 2035.

- Energy efficiency: The UK is improving the energy efficiency of homes and buildings, which can help to reduce emissions and lower energy bills. The government has set a target of upgrading all homes in England to at least Energy Performance Certificate (EPC) C by 2035.

- Carbon capture and storage (CCS): The UK is investing in CCS technology to capture carbon emissions from industrial processes and power generation and store them underground. The government has announced funding for two CCS clusters in the North Sea, which could capture and store up to 10 million tonnes of carbon dioxide each year.

- Green finance: The UK is promoting investment in green finance, which can help to fund the transition to a low-carbon economy. The government has launched a Green Finance Strategy, which aims to increase investment in sustainable infrastructure and technologies.

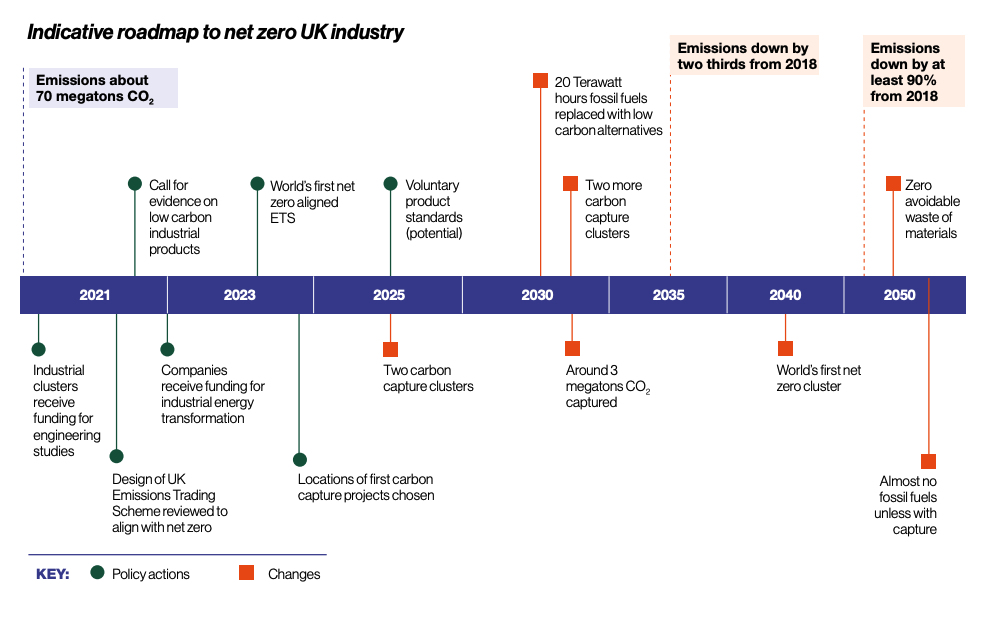

Industrial Decarbonisation in the UK

Did you know? The UK was the world’s first major economy to present a net zero Industrial Decarbonisation Strategy. In this report released by the government, you can find more details. The image grabbed from the report below shows the roadmap to net zero for the UK industry.

“The 2020s will be crucial for us to lay the bedrock for industrial decarbonisation. Over the next decade, we will begin the journey of switching away from fossil fuel combustion to low carbon alternatives such as hydrogen and electrification, deploying key technologies such as carbon capture, usage and storage, and supporting industrial sites to maximise their energy and resource efficiency to reduce costs for businesses. In parallel, we will continue to help the industry overcome barriers and work with our international partners, both old and new, to kick-start the demand for low carbon industrial products.” said The Rt Hon Anne-Marie Trevelyan MP Former Minister of State for Business, Energy and Clean Growth.

Although manufacturing’s contribution to the UK GDP has decreased since the 1970s when it accounted for 25%, the UK still ranks as the world’s ninth-largest manufacturing nation. Here is an overview of UK Manufacturing Statistics.

Industrial Decarbonisation in Europe

In 2005, the International Emissions Trading Scheme (EU-ETS) was created to encourage the largest emitters of greenhouse gases to reduce their emissions. The introduction of a carbon market is intended to measure, monitor and reduce emissions from industry and power generators, and has been a real catalyst for the decarbonisation of industry for almost 20 years. In July 2021, as part of the Green Deal, the European Commission presented the Fit for 55 package and proposed a new directive framing the carbon emissions market with the aim of strengthening the efficiency of the ETS.

* Note that the European Green Deal, which came into being in December 2019, already included a circular economy strategy and plan for the industrial sector to encourage the decarbonisation of the sector.

How to Decarbonise Industry: Solutions for your Company

Calculation of your Carbon Footprint

Before decarbonising your industrial site, it is important to assess its carbon footprint. This calculation measures the greenhouse gas emissions produced by your entire industrial site, including the production processes. By determining the carbon footprint, your industrial company can prioritise actions to reduce greenhouse gas emissions and reach your decarbonisation targets.

How to calculate the carbon footprint of your industrial site? The key is to use the right tools. An Energy Management System such as the Dexma Platform can help you to :

- converting the energy consumed into greenhouse gas emissions;

- propose emission reduction targets and monitor them in real time;

- automatically generate reports on CO2 emissions.

Digital Transition: the importance of Data for Industrial Processes and Energy Consumption

It is commonly accepted that digital and ecological transitions are closely linked. In the case of industrial companies, digitalisation plays a key role in the decarbonisation of factories. Indeed, it enables the collection, analysis and exploitation of data generated by industrial processes to optimise energy consumption, reduce production costs and improve environmental performance.

For several years now, the 4th industrial revolution (Industry 4.0) has resulted in many factories and industrial sites being interconnected and intelligent. Internal data tracking, energy metering and process automation are all techniques to help make informed decisions about decarbonising industrial sites. Regardless of your improvement goals for your plant, digitalisation and data access are effective ways to achieve them. In short, digital transformation is not an end in itself, but rather a means to an end.

If you want to know how to improve the energy performance of your plants and move towards smarter manufacturing management, we invite you to watch the recording of our webinar focused on Energy Savings in the Industrial Sector.

Energy Transition: The Importance of Decarbonised Energy

What if one of the key solutions to decarbonising the industrial sector was simply its energy transition? The energy transition consists of moving from an energy model based on fossil fuels to one based on renewable and decarbonised energy.

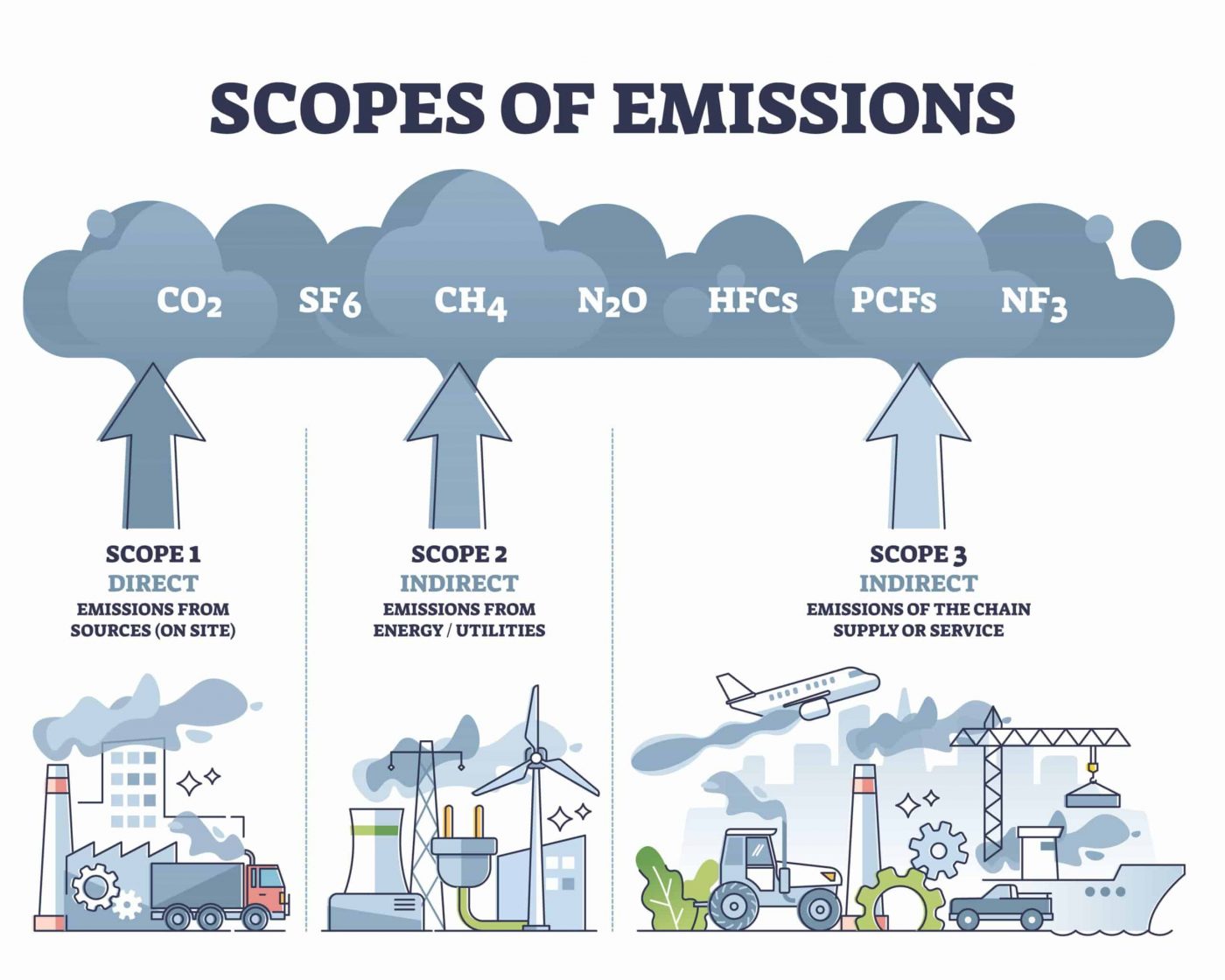

Given the large volumes and intensity of use of equipment, energy supply should be considered a key element in making this transition. By shifting your industrial company’s energy model, you address scopes 1 and 2 of the carbon footprint (see below) and maximise your chances of improving its outcome.

Some examples of structural investments in low-carbon energy sources that companies can consider are:

- Take advantage of Waste Heat: This is the heat produced by your machines during the manufacturing process of your products. But did you know that some of this heat can be used as a source of energy in your factory? It can be harnessed and used to heat buildings, generate electricity or provide heat for other industrial processes.

- Biomass Energy Use: Biomass consists of organic materials, such as wood, agricultural waste or residues from the food industry. These materials can be transformed into energy products to produce motion, heat or electricity.

- Photovoltaics for Renewable Energy Production: Have you already considered installing photovoltaic panels to decarbonise your industrial sites? Photovoltaic panels produce electricity from solar energy and can be installed on the roofs of industrial buildings to produce electricity that can be used for industrial processes or fed into the electricity grid.

In summary, the decarbonisation of the industrial sector represents a crucial challenge for companies wishing to participate in the fight against climate change and to meet national and European standards for greenhouse gas emissions. Companies can seize the opportunity of decarbonisation and green transition to improve their sustainability and competitiveness by exploring various options. A responsible approach by industrial companies will ensure their sustainability while contributing to the preservation of the environment.

Looking for concrete examples of companies that have undertaken the ecological and energy transition? Check out our resources page which is full of free content. And don’t miss the recording of our webinar, where our experts discuss energy saving in the industrial sector. Click HERE or on the picture: ⬇️

![Reducing Energy Costs in the industrial sector [WEBINAR] - Dexma](https://no-cache.hubspot.com/cta/default/437281/511f8d36-d48e-4e35-ab7b-f8454734544d.png)

![Reducing Energy Costs in the industrial sector [WEBINAR] - Dexma](https://no-cache.hubspot.com/cta/default/437281/e30616e5-b5e0-499e-b4f2-e155fae23d64.png)